Here’s how piqué fabric typically fares in terms of static electricity:

- Static Generation: Piqué fabric is less prone to generating static electricity compared to synthetic fibers like polyester or nylon. The raised texture of piqué fabric and its breathable construction reduce friction between the fabric and the skin or other surfaces, minimizing the buildup of static charge.

- Static Dissipation: Piqué fabric may dissipate static electricity more effectively than certain synthetic fibers. The textured surface of piqué fabric provides more pathways for static charge to disperse, allowing it to dissipate more quickly and reducing the likelihood of static shocks or clinginess.

- Humidity Sensitivity: Piqué fabric’s static resistance may vary depending on environmental humidity levels. Like most natural fibers, piqué fabric tends to be less susceptible to static electricity in humid conditions, as moisture in the air helps conduct away static charge. pique fabric manufacturers In dry environments, however, static buildup may be more noticeable.

- Natural Fiber Comparison: Compared to natural fibers like cotton or wool, piqué fabric may exhibit similar or slightly better static resistance. While natural fibers generally have lower static buildup compared to synthetic fibers, the specific weave and construction of piqué fabric may further reduce static generation and clinginess.

Overall, piqué fabric typically handles static electricity better than certain synthetic fibers but may not be as static-resistant as some natural fibers like cotton or wool, particularly in humid conditions. Its textured surface and breathable construction contribute to its ability to minimize static charge buildup and dissipate static electricity, making it a practical choice for garments where static cling or shocks are a concern.

What factors affect the tear and snag resistance of pique fabric?

The tear and snag resistance of piqué fabric, like any other fabric, are influenced by several factors related to its composition, construction, and use.

Here are some key factors that affect the tear and snag resistance of piqué fabric:

- Fiber Type: The type of fibers used in piqué fabric plays a significant role in its tear and snag resistance. Natural fibers like cotton or bamboo tend to have good inherent strength and resistance to tearing, while synthetic fibers like polyester or nylon may offer enhanced durability and abrasion resistance.

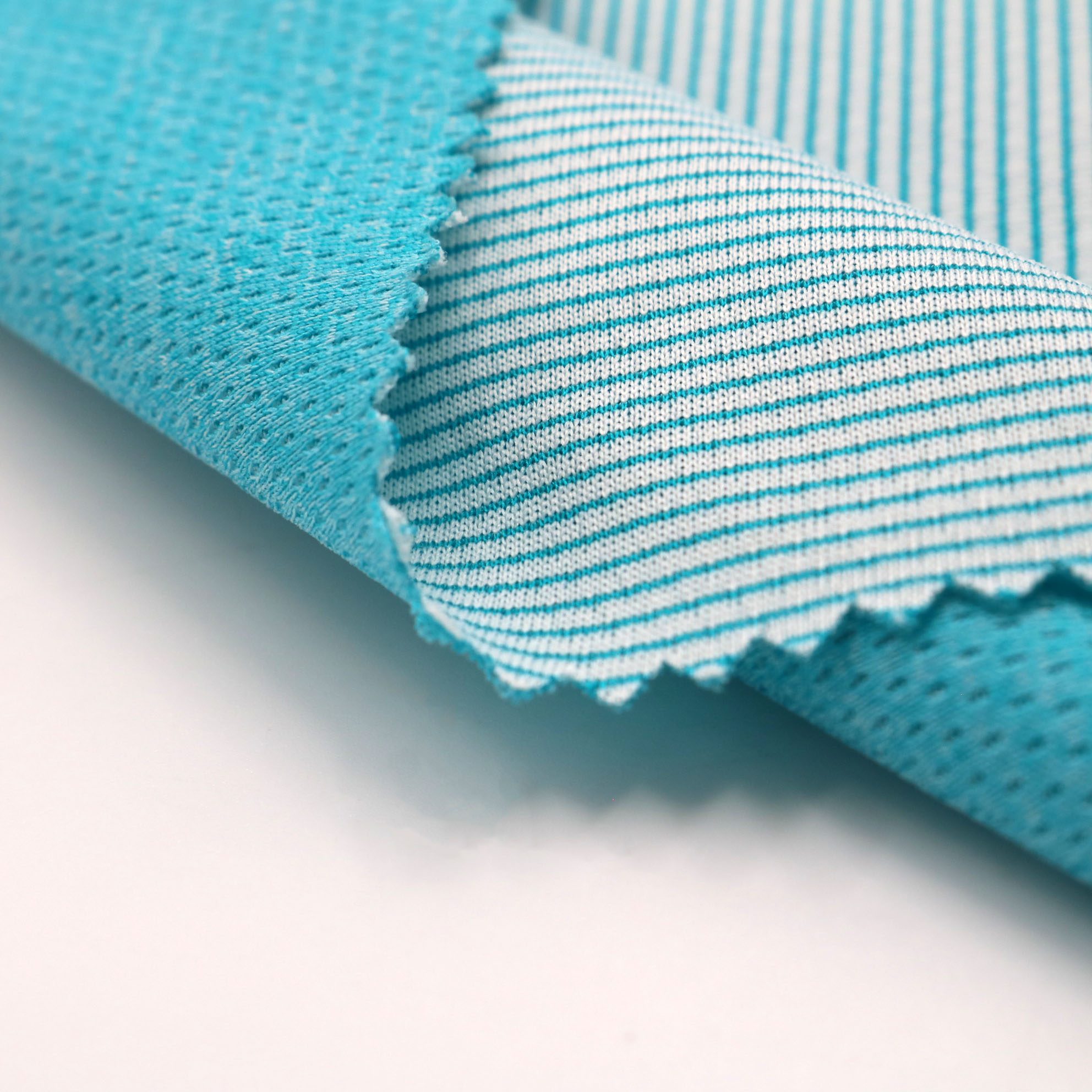

- Fabric Construction: The construction of piqué fabric, including the weave or knit pattern, yarn count, and density, affects its tear and snag resistance. A tighter weave or knit construction generally results in a more durable and snag-resistant fabric, as it reduces the likelihood of yarns pulling apart or catching on external objects.

- Yarn Type: The type of yarns used in piqué fabric can impact its tear and snag resistance. Single-ply yarns may be more prone to breakage and snags compared to multi-ply yarns or textured yarns, which offer greater strength and resilience.

- Fabric Finish: Certain finishing treatments applied to piqué fabric during manufacturing, such as anti-snag or anti-pilling finishes, China pique fabric suppliers can improve its tear and snag resistance. These finishes help smooth the surface of the fabric and reduce the likelihood of yarns catching or pulling.

- Fabric Weight: The weight of piqué fabric can affect its tear and snag resistance. Heavier-weight fabrics typically offer greater durability and resistance to tearing compared to lighter-weight fabrics, as they contain more fibers per square inch to absorb stress and impact.

- End Use: The intended use of piqué fabric also influences its tear and snag resistance. Fabrics used for heavy-duty applications, such as upholstery or outdoor apparel, may be engineered to be more tear-resistant than fabrics used for lighter-weight applications, such as t-shirts or casual wear.

- Care and Maintenance: Proper care and maintenance practices, such as washing piqué fabric with mild detergent, using gentle cycles, and avoiding harsh chemicals or abrasive surfaces, can help preserve its tear and snag resistance over time. Avoiding excessive stretching, pulling, or friction during wear and storage can also minimize the risk of tears and snags.

Overall, the tear and snag resistance of piqué fabric depend on a combination of factors, including fiber type, fabric construction, yarn type, fabric finish, fabric weight, end use, and care and maintenance practices. By considering these factors, manufacturers can produce piqué fabric with optimal durability and performance for various applications.